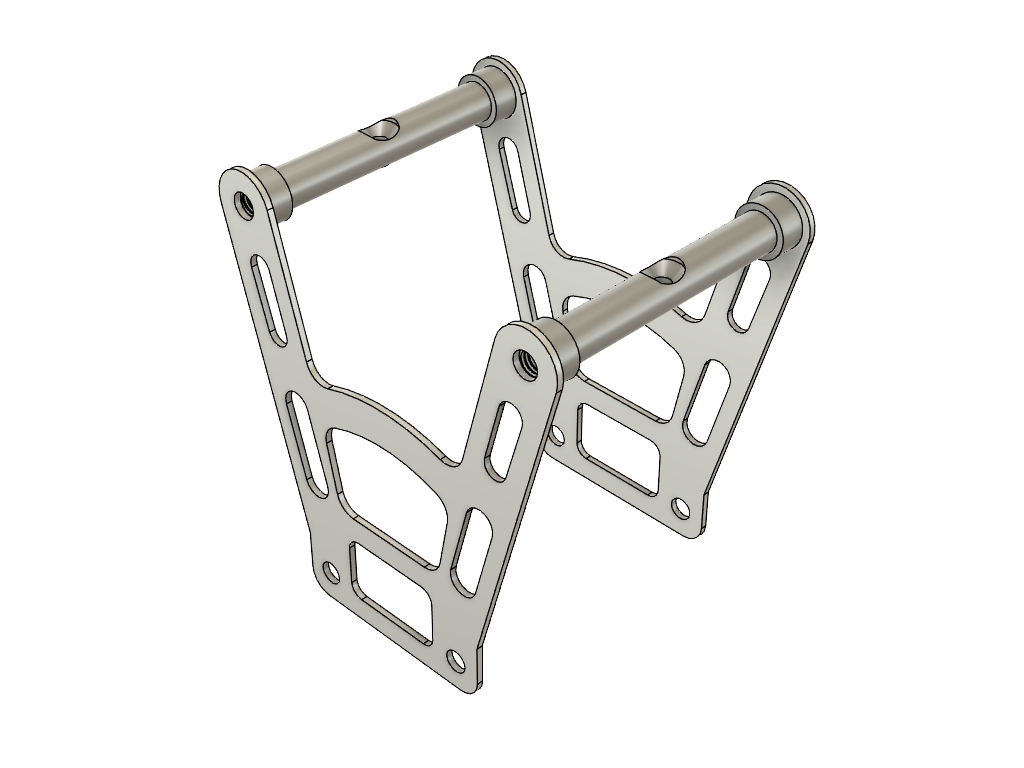

I’ve been interested in fork brace for 35mm Showa Narrow Glide Forks for a long time. This time, I accidentally acquired an aluminum fender for 19 inch tyres. So I decided to make a fender support bracket which can also be used as a front fork stabilizer.

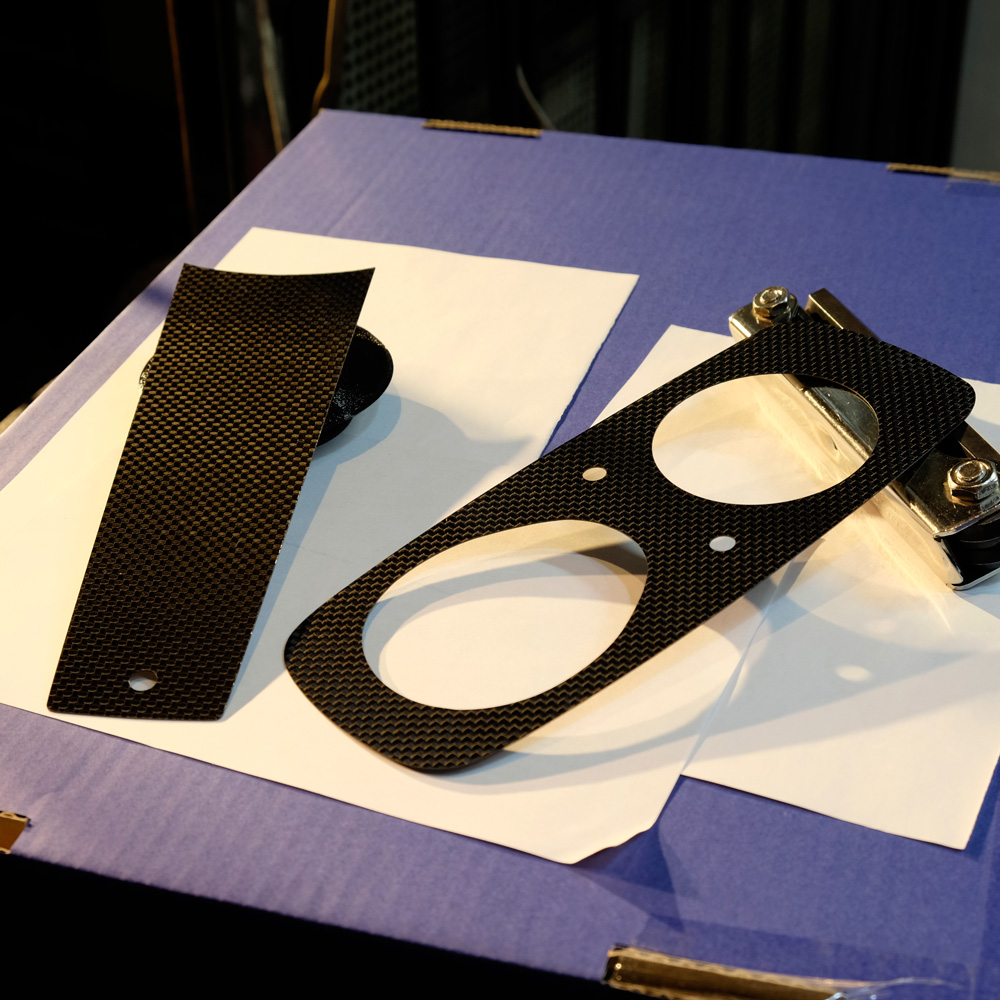

As narrow glide forks literally don’t have much more space than necessary between both fork tubes, considering the strength of the parts, I tried to go with a 2.3mm thickness stainless steel plate as main body instead of aluminum plates.

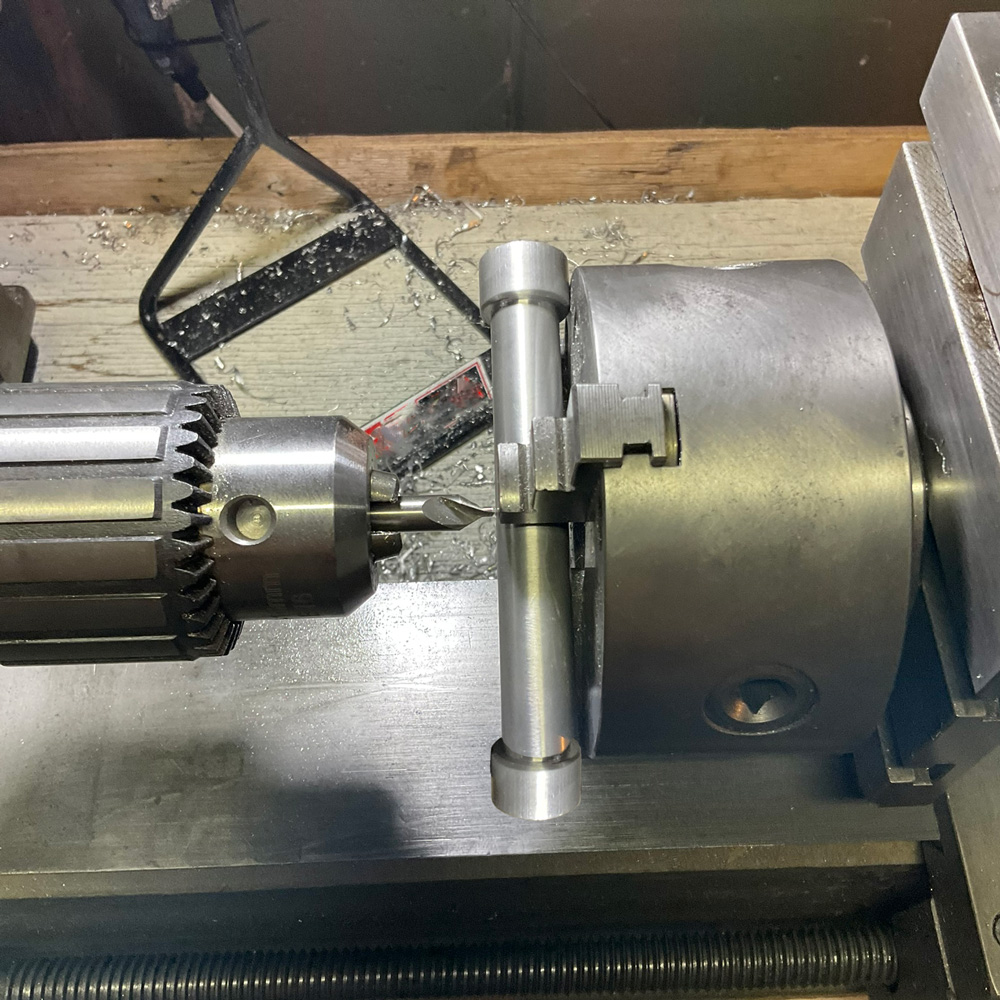

I made two aluminum rods which would bridge both stainless steel plates. The material of the rods are aluminum alloy 6061.

I drilled to make a hole on the center of each rod to put through a screw to hold fender.

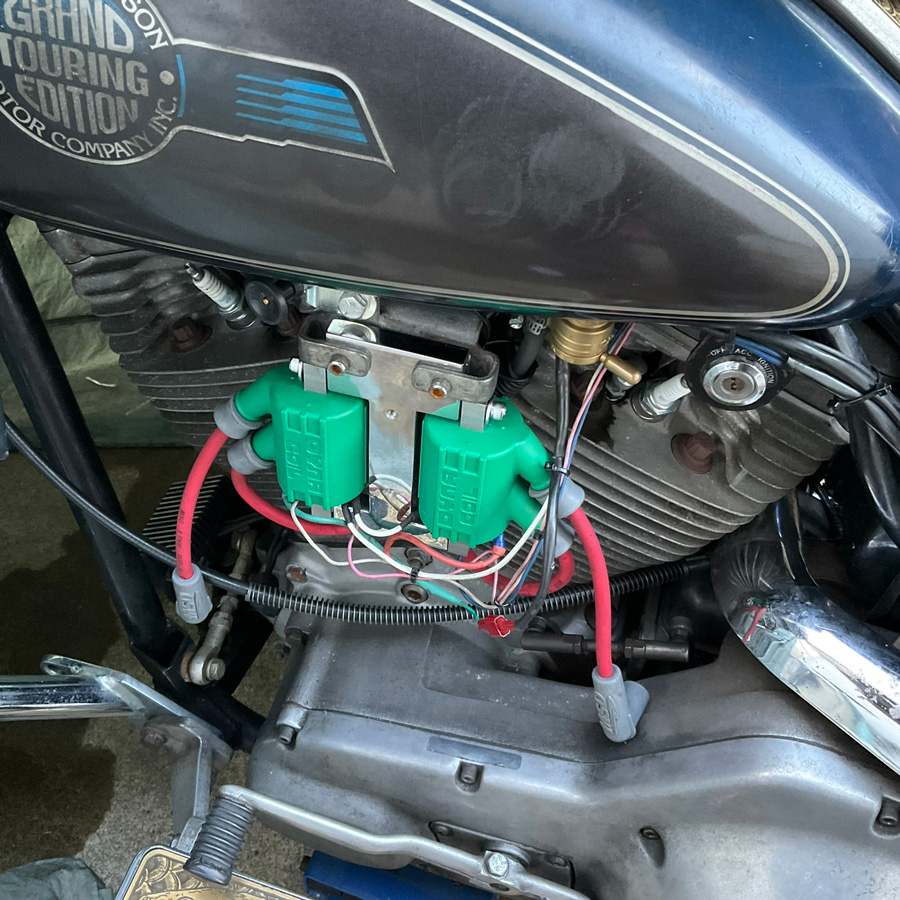

This is the aluminum fender which I acquired not long ago. I suppose it was a fender for Yamaha SR400 which was equipped with 19 inch front tyre like Harley-Davidson FXR models.

I drilled two holes on the center of the fender for screws. Regrettably, several holes are remaining on either side of the fender which have been used on SR400. I must weld and fill them in the future.

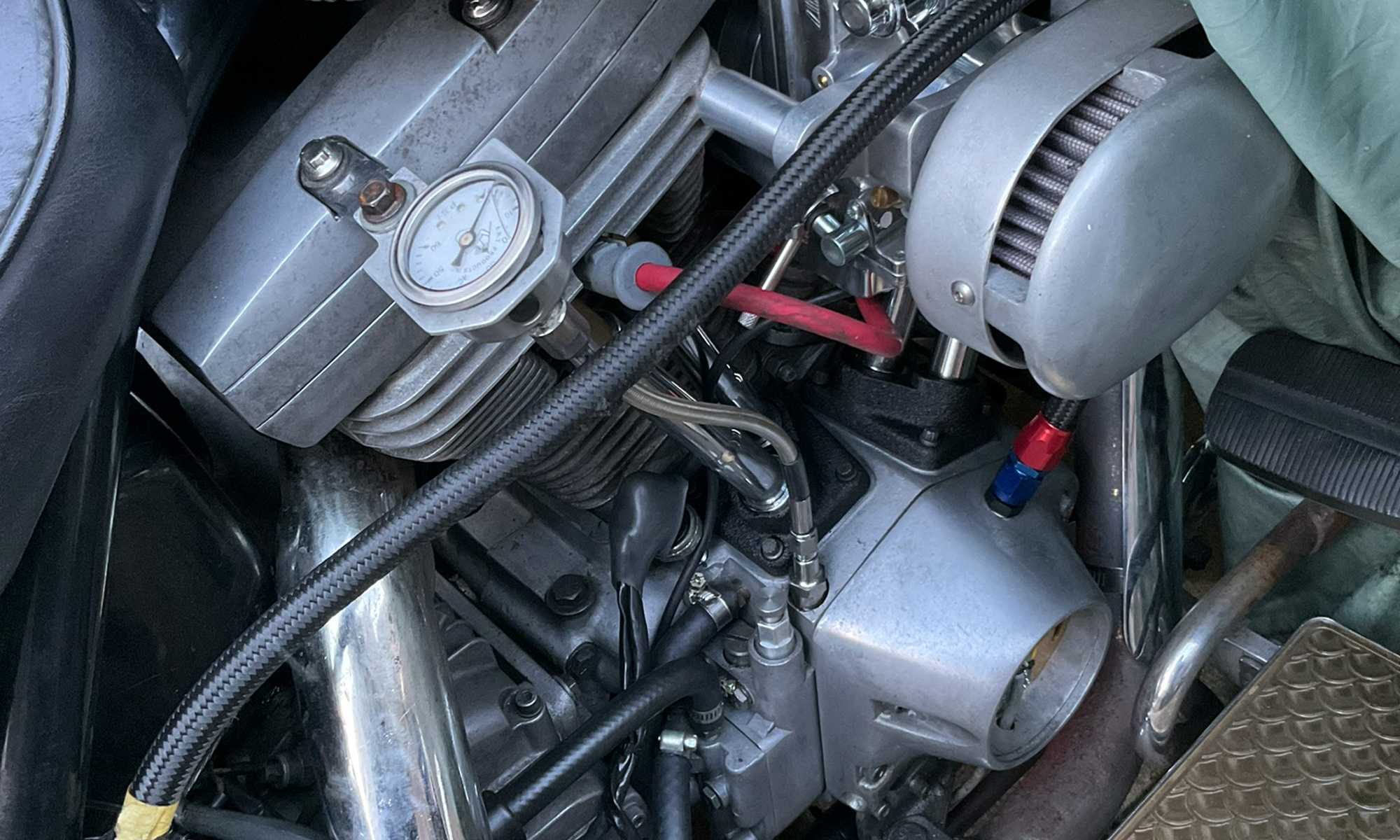

Finally, I put them on my FXRD. It seems that nothing could be a trouble. There is enough clearance between the bracket, fender and tyre.

At last, I’ve done test riding and checked how it worked.

I could feel slightly that the bracket stabilized wobbling of the forks especially turning right or left.

I’m going to continue test riding for a while since I think there are several critical elements demanding for motorcycle parts and durability is one of the most important elements of them all.